Paper laboratory Paper laboratory

WHAT IS IT?

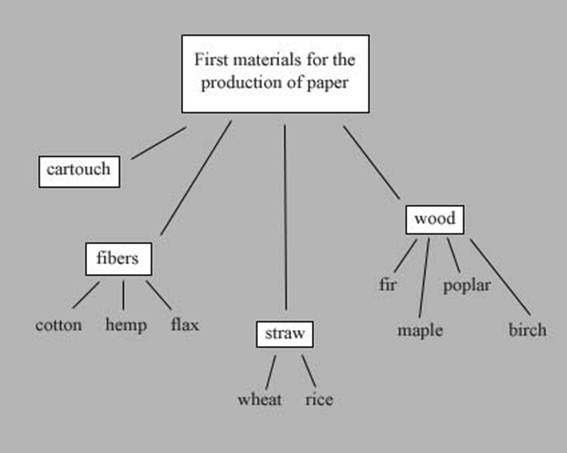

Paper is a thin and flat material made by the compression of fibres which are usually natural and derived from cellulose. The material most commonly used is wood pulp, usually tender wood such as fir or poplar, but other fibres including cotton, flax, or hemp can be used. A stack of sheets of paper is called a ream, and the thickness of the paper is defined

HISTORY

While the etymology of the word carta is somewhat uncertain, but according to some it could be derived from somewhere between the Latin charta and the Greek charassò, which mean “to incise” or “to sculpt”. The corresponding terms paper in Anglo-Saxon and papier in French are instead derived from the papyrus plant, used for writing by the ancient Egyptians since 3,000 B.C. and successively by the Greeks and Romans. The papyrus is a species of reed that grows along the Nile River. The skin is stripped off the stem and the middle section is cut into long and thin strips, which can be woven and then hammered until flat. A leaf is then dried under a heavy weight, and then it is smoothed out with a piece of pumice wetted with cedar oil. The scroll of the scribes was made by sticking together successive leaves one over another onto which could be written only the horizontal register.

The first book making happened thanks to the invention of parchment (from the Middle Eastern city of Pergamon). Hairs from the cow, goat, ram, or gazelle were shaved, stretched, dried, cleaned with pumice, and then treated with calcium. The resulting membranes were long, fine, and light, but sufficiently resistant to allow writing on both sides.

In China they wrote on sheets of bamboo up to 75 centimetres wide and tall enough to vertically draw out the characters; battened, folded in a roll and bound, they formed books that were solid and economical but also heavy and cumbersome. Occasionally they used silk, much lighter and adept for writing, but also much more costly; as such it was reserved for the sacred texts, illustrated art books, and the imperial annals.

Tradition holds that in 105 B.C. the agricultural minister T’sai Lun invented the fabrication method of paper “paste”: vegetal fibres mixed with textile fibres (masticated ropes and cloths) were ground into a paste wetted with water. The Chinese successfully kept their secret method until 751 during a war in which the Arabs captured and imprisoned some paper makers and learned the procedure from them, which they then improved by using fibres from cotton, hemp, and flax.

Paper from the east was introduced to Europe in the 13th century and developed by Amalfi and Fabriano, made from flax and canvas fibres; paper remained however as a luxury good for many centuries, until the invention of the steam engine in the 19th century, at which point it was possible to mechanize paper making with the use of wood fibres. With the contemporaneous invention of the stylographic pen, to the mass production of the pencil, to the widespread use of the printing press; paper had a notable economic and societal weight on industrialized countries. Before this era, a book or a newspaper was a rare and precious object and illiteracy was widespread; with the gradual introduction of the new economic paper; newspapers, books, and notebooks are owned by practically everyone.

PRODUCTION

For many centuries the principal materials were fabrics, for which people would travel the countryside collecting old linens to resell to mills where paper was fabricated. The mills divided the linens according to colour, and in time they used only the whites. They remove the stitching, humidify the fabric and then leave it in a cellar to mould. From there it is cut into thin strips and put into a vat of water, where it is pounded by heavy hammers for hours and eventually reduced into filaments. These elements, mixed with water, form the paste to make paper, but at this point it is still too watery. Adding glue or resin makes a finer paste. A worker would immerse a sieve in the vat of paste, and remove it while shaking in order to create a regular distribution. Once drip-dry, the sheet is still fragile and wet, and goes to lie between two sheets of felt. The alternating layers of felt and paper are put under a press to strain out all of the water via compression. At the end the sheets are laid out to finish drying.

The most common material for paper production is wood pulp, usually from soft wood such as poplar or fir. Cultivation of the poplar is especially important in Italy and is practiced mostly in the Po valley.

First of all the material is transformed into pulp, a concentrated mixture of fibres suspended in liquid. Separation of the fibres can be done physically (by beating or applying heat) and chemically (with alkalines); they require different passes through separation and cleaning, then bleaching or tinting to alter the original aspects of the fibres and obtain those of the final product.

The pulp is ultimately diluted with water to create a soft paste; an extremely fine sieve is then immersed in this suspension, onto which settles an interlacing fibres. In this phase filigree can be impressed upon the paper by simply stamping the motif in shallow relief on the screen of the sieve (the old masters of Fabriano used this technique). To complete a sheet of this interlacing fibre paper it must be pressed and dried. In the process called filtration, a precise quantity of pulp is skilfully put through a form in the bottom of which is a fine sieve through which the water can drain. Then pressure is applied to expel extra water, after which the sheet may remain to be further worked.

The industrial production usual happens as a continuous process called fourdrinier, in which the paper is fabricated in long ribbons on reels. Once dried the ribbon gets cut horizontally to the desired dimension. Paper dimensions are standardized by the International Organization for Standardization (ISO 216).

Raw paper obtained by pressing pulp is very absorbent (and is used as blotting paper) and does not have a surface suitable for writing or stamping; for this reason additives are utilized to achieve the desired characteristics and are applied as a topcoat on the surface, forming the patina. Starch, poli-vinylacetate (PVA), and many other products are used to create different types of paper. The patina works best on a smooth surface, using kaolin (to obtain, for example, paper patina for newsprint). The polished aspect is obtained by applying successive transparent layers (like enamel) to a printed page.

Other additives are put in to improve other characteristics of the paper, in particular the purity of the colour white.

THE PAPER MILL

A machine that retools the work of the old mills, but instead of making the sheets singularly, they produce 800 meters of paper a minute. The operations are entirely controlled by a computer:

The pulp drains on a fabrication shelf: a giant flowing carpet. Underneath, tiny suction rollers remove water.

The pulp becomes a sheet that circulates on a wool felt.

The sheet is slimmed down between press rollers.

The paper is dried between heat cylinders.

The paper is smoothed to acquire a uniform thickness.

The paper is rolled on a large bobbin and sent to typographers.

Much rarer, in respect to wood for the extraction of cellulose, is straw; used mostly for the fabrication of corrugated cardboard and straw paper.

Paper is a material that can be recycled and from paper money can be made new paper, rather than cutting down more trees; one ton of recycled paper saves the life of eight trees.

PROPERTIES OF PAPER

Hygroscopic: is the ability to absorb moisture more or less easily. This characteristic gives alterations to the weight and dimensions of the paper.

Capillary absorbance: is the ability to absorb water through the fibres. A strip of paper vertically immersed in water for a small period shows the fashion in which the paper wets. It is in fact the way that the water travels through the tiny tubes composing the fibres, an example of the phenomenon of capillary action.

Permeability: is the ability to allow water to pass through. Papers with little glue are more permeable, less so for papers with more glue; papers produced with a mixture of substances are impermeable (such as wax paper).

Porosity: is the ability to allow air to pass through. The porosity depends on the binding, or gluing, of the paper.

Smoothness: is the grade of finish on the surface of the paper, given by the pressure of the cylinders.

USES

Paper is used for a great many things, some of which are:

Writing: a sheet of paper becomes a document and assumes value for that which is written, for example, bank notes, checks, tickets, receipts, et cetera. Printed paper is bound to form books, newspapers, magazines, brochures, et cetera.

Packing: envelopes, wrapping paper, wallpaper, et cetera.

Cleaning and hygiene: toilet paper, handkerchiefs, napkins, et cetera.

Construction of objects: origami, decoupage, papier mâché, et cetera.

CONSERVATION PROBLEMS

Paper is subject to deterioration as a result of many factors:

Physical damage, use, and wear.

Ultraviolet rays which provoke oxidation of the cellulose.

Dust, which creates a welcoming environment for insects and bacteria.

Moisture which favours the development of mould.

Aggressive pollution, which at times can be from instable chemical inks and deposits left from the fingers of the readers.

Animals and insects (mice, woodworms, and termites) which eat away at the paper

Bacteria and fungi.

Every day paper becomes less acidic and more stable with time; papers adapted particularly to long term conservation are also available, for use in tandem with inks formulated for stability and in aggressiveness.

ENVIRONMENTAL IMPACT

The paper industry has been accused of contributing to deforestation; but this problem has been remedied by substituting the trees cut down with other younger plants grown ahead of time. Time must be taken for these new plants to grow into full size; beech become adults in sixty years, pines in only twenty. Technicians search for new production methods, with plants that grow into adulthood in one year, such as hemp, alfalfa, and algae. The paper mills then can use recycled paper.

The production process of paper is often the cause of problems, when bleach products used in the process of whitening the wood pulp pollute lakes and rivers. These problems have been for the most part resolved by eliminating of the use of chlorine in the working process.

HOW TO MAKE YOUR OWN PAPER

Materials: newspapers, gardening net, a bucket, a pot, an old blanket, a wood table.

Wet a newspaper, tear into pieces, and put them in the bucket over which hot water is to be poured. Leave the papers to sit in the bucket overnight. If the paper is not transformed into a soft paste, boil everything in the old pot and leave to rest and cool in a way that a regular layer floats at the top. Immerse the net in the pot and extract slowly while keeping it horizontal, so that the pulp forms a thin and regular layer. Strain the water and lay out the paper on a piece of the old blanket. Add more layers so that the paper unifies into one piece, then cover again with the old blanket and over the top place the wooden table. Press the table to squeeze out all the remaining water. Lift the table off and leave the paper to dry.

BIBLIOGRAPHY

Storia di un foglio di carta, Edizioni EL

La carta avventura quotidiana, Universale Electa/Gallimard

Internet: Wikipedia; www.icbaracchini.lunigiana.it

Divertiamoci con la natura, De Agostini Ragazzi

Kaolin (from the locale of Kao-ling = a high hill in China, where discovered in the 7th century): rock or mixture of aluminum-silicate minerals, utilized in more pure varieties for the fabrication of porcelain and majolica, in bricks and other refractory materials.

Alfalfa or Lucerne (from the arabic Halfa): an herbaceous perennial plant of the grasses family, also called Sparta (though this is a different plant of its own), diffused mostly throughout northern Africa; the fibres extracted from the leaves are used for the fabrication of twines and also some types of soft, heavy printing papers.

|